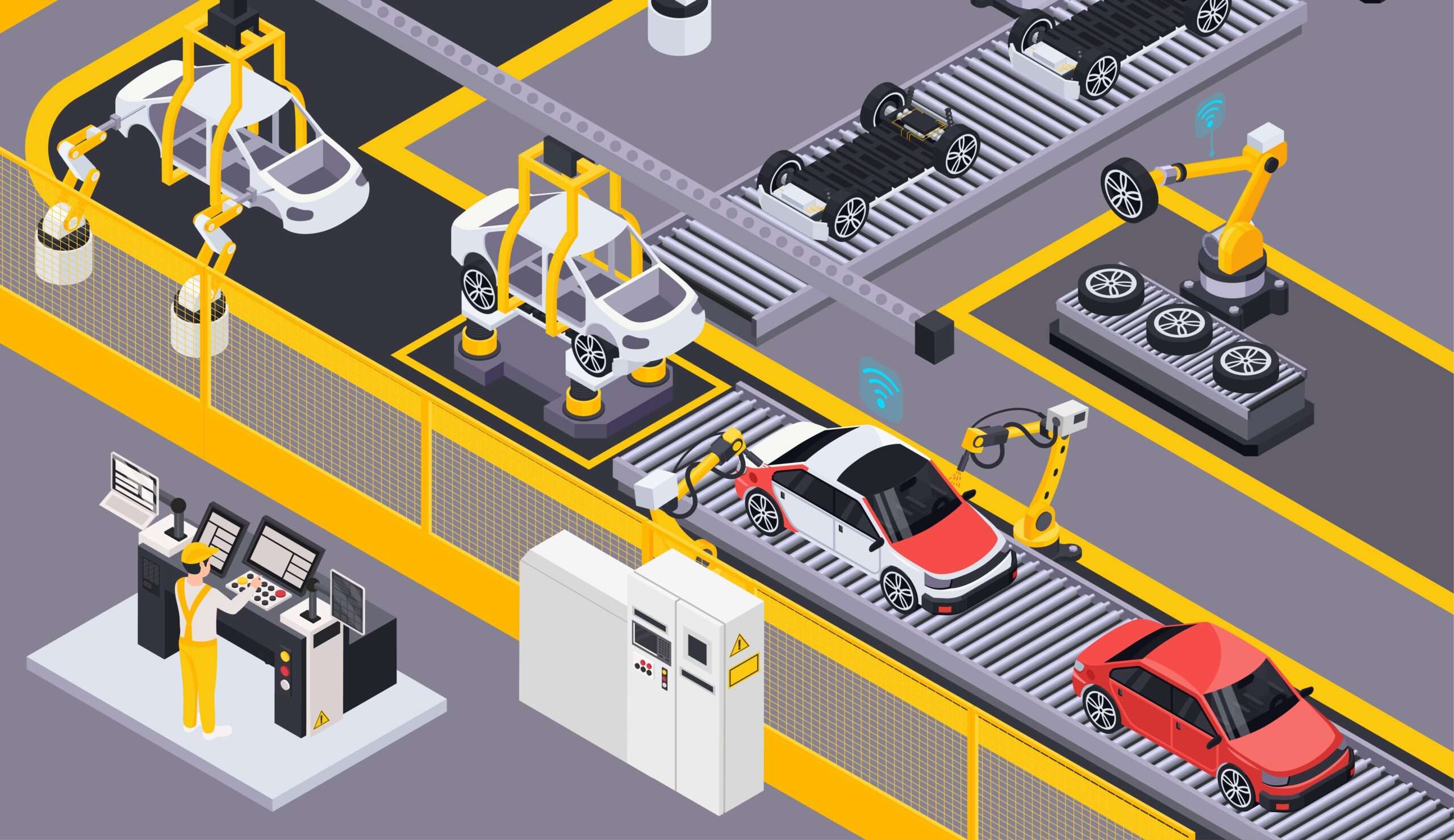

In automotive manufacturing, even the smallest flaw can trigger expensive recalls and damage brand reputation. To tackle this, manufacturers are increasingly turning to AI-powered image and video analysis, also known as computer vision. It acts as a second set of eyes on the production line.

High-speed cameras continuously capture images of components, which are then analyzed by deep-learning algorithms in real time. By automating quality inspection, manufacturers not only improve precision but also significantly reduce scrap, rework and operational costs. By integrating AI-powered image and video Analysis at every stage, automotive manufacturers ensure that only fully compliant, defect-free vehicles reach showrooms, all while minimizing downtime and rework.

How AI-Powered Image and Video Analysis Helps the Automotive Industry

AI-powered image and video analysis delivers tangible results across automotive production. From efficiency gains to cost savings, the advantages are clear:

AI Image Analysis for Quality Control

In automotive manufacturing, appearance is just as critical as performance. AI image analysis ensures that every vehicle leaves the paint shop with a flawless finish. After painting, high-resolution cameras paired with specialized lighting capture the car body from multiple angles. Deep-learning algorithms then analyze these images to detect even the slightest imperfections, such as color mismatches, scratches, or orange-peel textures in the paint.

By embedding AI into surface inspection, automotive manufacturers not only uphold brand quality standards but also streamline production efficiency, delivering vehicles that look as perfect as they perform.

Video Analytics for Monitoring and Safety

While image analysis focuses on single snapshots, continuous video streams enable factories to monitor entire production processes in real time. AI-powered video analytics can track material flow, detect defects as they occur and even identify potential safety hazards before they escalate.

Visual AI offers the ability to identify defects, monitor production lines and ensure quality control with unparalleled accuracy and speed. In practice, cameras positioned along the line capture live video. Computer vision models then scan for irregularities, whether it’s a color variation on a painted part or an unsecured bolt that could compromise safety.

AI-driven video analytics are not limited to quality inspection, they also play a vital role in protecting workers and safeguarding equipment. Additionally, they help in predictive maintenance. Subtle warning signs, like small oil leaks, overheating components, or frayed belts, are automatically flagged, enabling maintenance teams to intervene before minor issues escalate into major breakdowns.

Key Benefits of AI Analysis

AI-driven image and video inspection is not just a technological upgrade, it delivers measurable improvements across the automotive shop floor. These include:

- Faster inspections: Cameras and ML models check parts in milliseconds, so inspection no longer bottlenecks the line.

- Higher accuracy: Vision systems catch subtle defects that humans often miss. In fact, machine vision can boost defect detection greatly.

- Lower defect rates: By automating checks at every stage, scrap and rework drop significantly. Fewer faults mean lower warranty and quality costs.

- Consistent quality: Cameras never tire or get distracted, every part is inspected with the same rigor, ensuring uniform quality even at high volume.

- Data traceability: Each inspection is logged and stored, enabling engineers to trace problems (e.g. to a supplier or process step) and continuously improve.

Connect With Technoforte Today

Ready to bring AI-powered precision to your manufacturing? Connect with Technoforte today and find out how our advanced image and video analysis solutions can help you boost quality, reduce costs and stay ahead in the automotive industry.

Email: sanjay@technoforte.co.in, shalini.shukla@technoforte.co.in

Phone Number: 9341257187, 7975552867